ATEX Overhead Drum Rotator (Wireless Weigh Scale)

DRU02-WLC-SS-FB-Ex

Lift and tilt drums using our crane slung drum rotator with weigh scales. The unit is suitable for customers with a requirement to measure material weight during decanting. This model can be connected to a PC system to log weighing data in real time; extremely useful in environments where quality assurance is critical. We supply this ATEX unit in stainless-steel; standard steel models are also available.

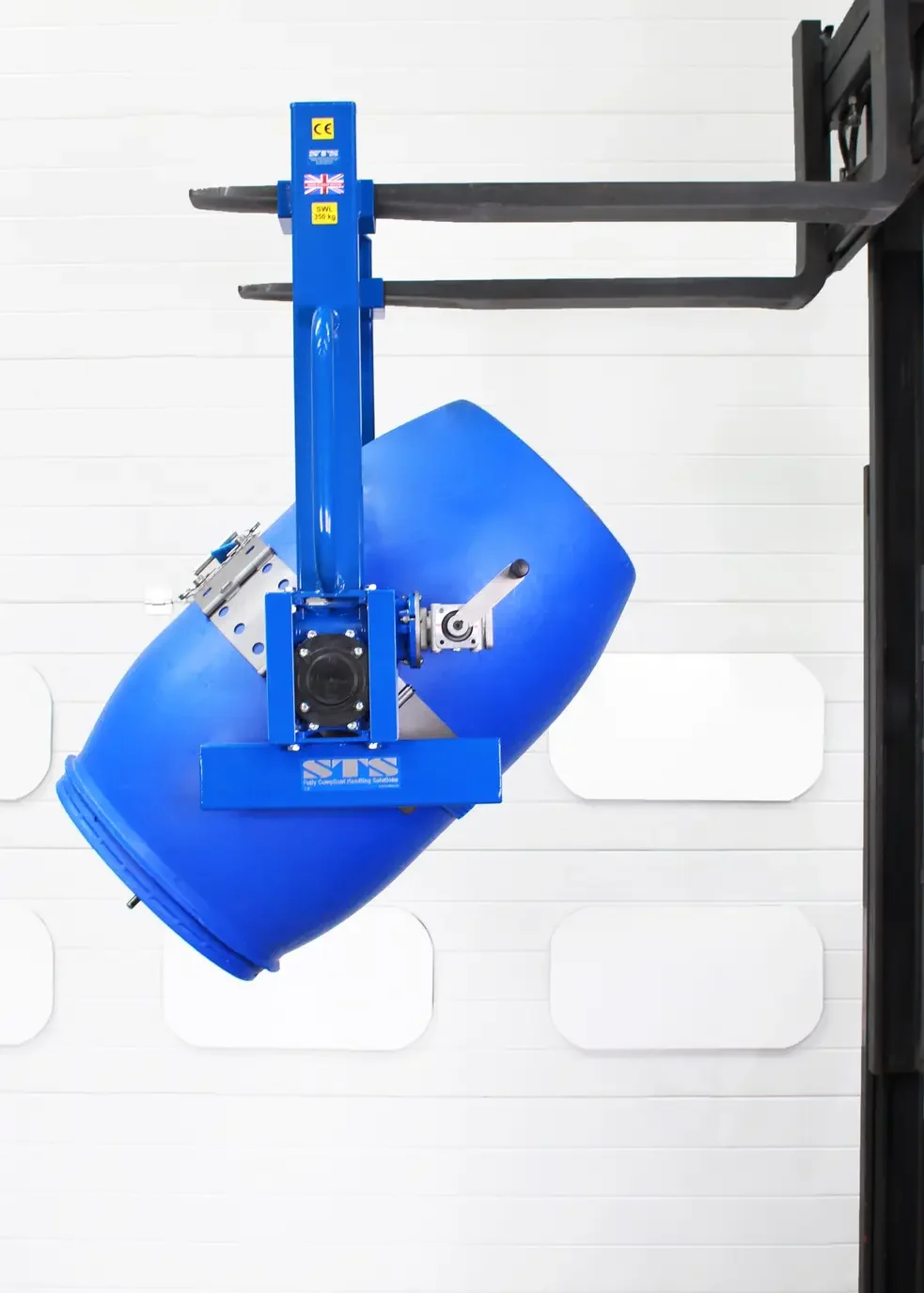

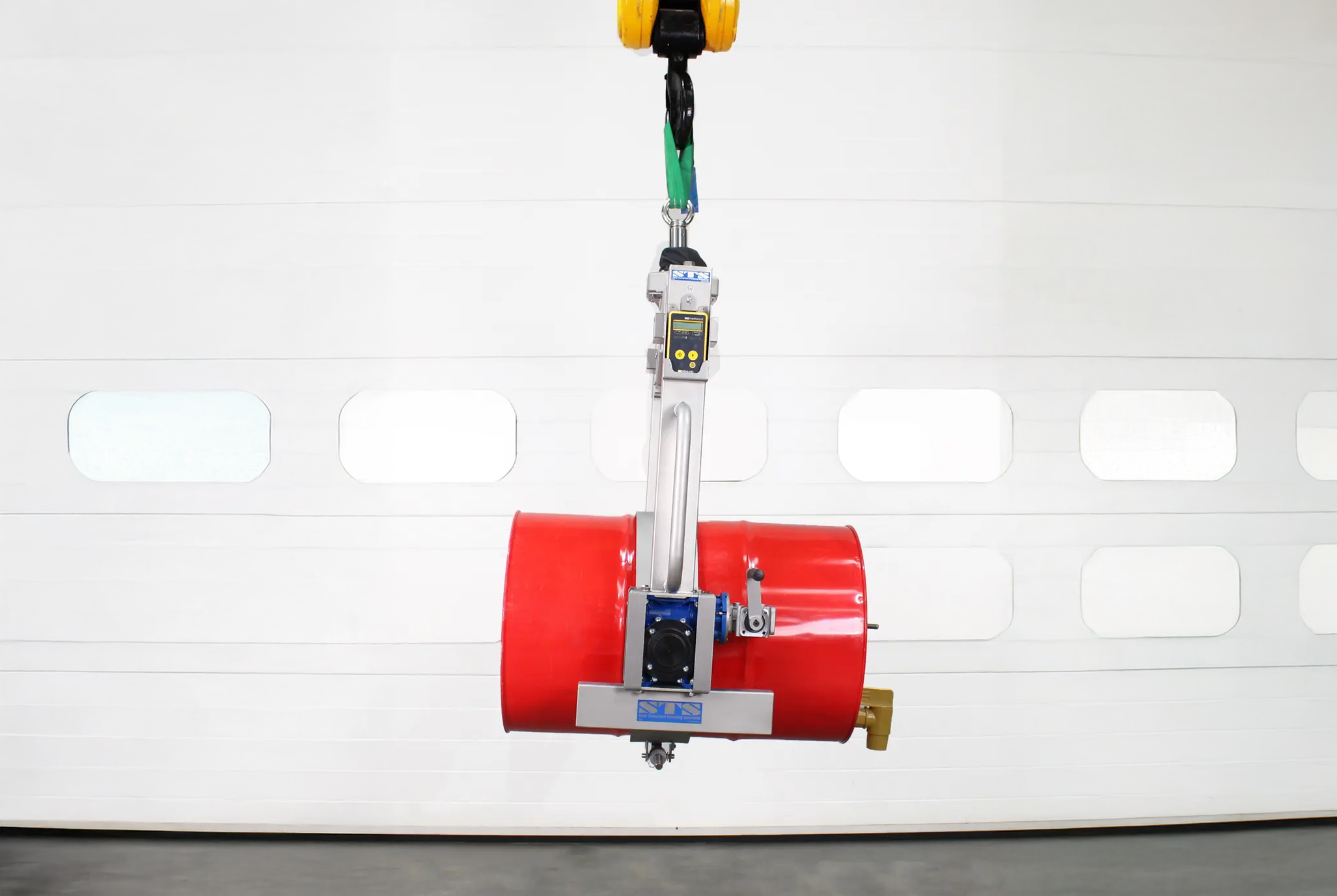

Large lifting pin and fork pockets

The crane slung drum tipper features two distinct pick-up points which makes it a great addition to any company with existing lifting equipment such as cranes and forklifts. The large central lifting pin allows for use with an overhead crane, derrick or hoist. The load-cell system is connected via the central lifting pin. Fork pockets are also included beneath the top bar for use with stackers and forklifts (these are not connected to the ATEX weigh scale system).

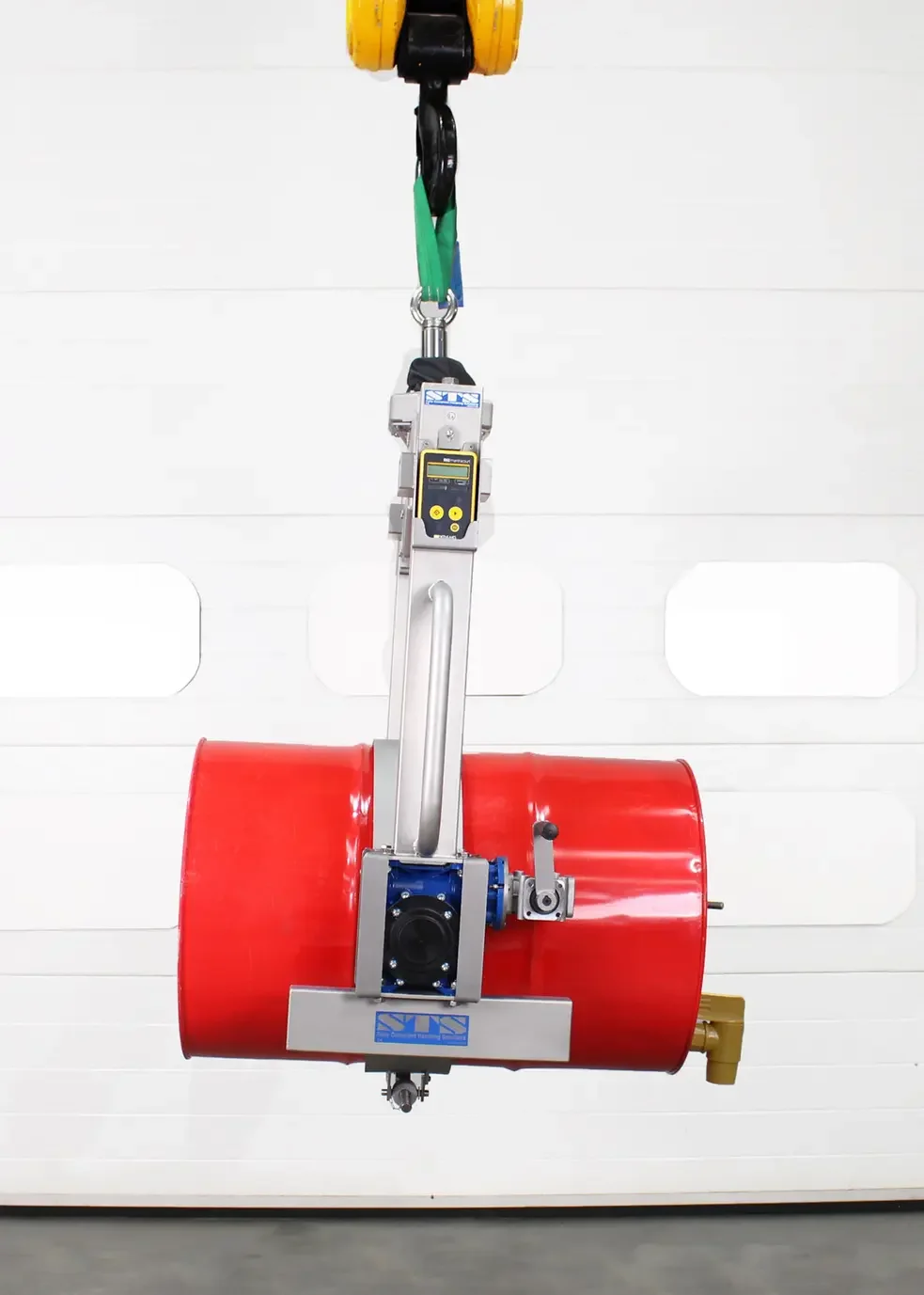

Drum Band Assembly

We supply our crane slung drum tippers with a fixed clamping band. The fast-acting over-center clamp (shown in the image) is adjustable to allow drums from 22.6” - 23.8” (580-600mm) in diameter to be clamped 52-58 gallon (200 to 220liter drums). Made out of stainless steel and manufactured in the UK, the securing system is extremely durable and robust.

Wireless weigh scale system

We have designed and manufactured this overhead drum tipper to include an integrated weighing system for use when lifting with a crane or overhead hoist. This load-cell feature allows operators to easily measure and control material flow with accuracy and confidence. Data logging via a computer system is possible making the unit very useful in modern factories and production facilities.

The load cell is housed within the top section of the DRU02 frame, therefore protecting it during use. We have developed this model to be completely fail-safe; in the highly unlikely event that the load cell fail or be damaged, the load remains secure thanks to the captive securing arrangement fitted below the crane hook.

The wireless system utilises 2.4GHz radio waves, a transmitter sends weight data to a handheld receiver; PC connection kits are available for data logging purposes. The weigh scales have an accuracy of +/- 0.1kg and are fully ATEX / UKEX compliant.

Self-Locking Gearbox

Rotating drums by hand is easy when using our ergonomic gearbox with a ratio of 120:1. The gearbox assembly is made up of a 60:1 primary gearbox and 2:1 secondary 90-degree transfer gearbox. We use self-locking gearboxes to ensure drums never self-rotate when an operator lets go of the rotation handle. The folding gearbox handle can be tucked away when not in use to prevent it from catching on obstructions.

ATEX-certified for gas and dust zones 1 and 2 (optional)

This ATEX-rated overhead drum tipper is suitable for gas areas: Zone 1 and 2. Constructed from 304-grade stainless steel greatly reduces any thermic-strike risk. All our 'Ex' rated drum handling equipment is supplied with a manufacturer’s Declaration of Conformity stating compliance with the directives and relevant British and ISO Standards. Standard (non 'Ex') models are supplied in steel and are grit-blasted and powder-coated.

Drum Suitability

Our Overhead Drum Rotator is suitable for a wide range of drum types, sizes and materials. For a detailed list of compatible drum types, see the drum suitability document below.

Optional Features

Stainless steel

This model can be supplied in 304-grade stainless steel, suitable for good manufacturing practice (GMP) areas as well as clean rooms.

Fixed-size drum band

If you’re only handling 200 to 220 liter steel and plastic drums, our fixed over-center drum band makes securing and handling drums quicker.