Fully Powered Drum Pourer with Powered Clamp

Product Code: STE05 / STP05-RRH01-Ex

Our fully powered drum tipper with power clamp is popular with companies that want to increase efficiency and eliminate manual handling risks. We can supply the unit with two powered options: electric hydraulic which utilizes on-board batteries, or a pneumatic-hydraulic model which can be certified for ATEX areas. A power clamp head assembly with flexible bands is fitted to the unit which can handle drums and barrels from 13-58 gallons (50 to 220 liters).

Electric

Suitable for safe areas, this fully-powered drum tipper comprises an onboard battery bank along with two separate electric motors. When the unit is not in use, simply connect the mains power to the charger to ensure the unit remains in a fully-charged state at all times.

Pneumatic

Our pneumatic units can be certified for use in ATEX and UKEX areas. Operators connect an airline to power a pneumatic-hydraulic circuit which powers the lift, clamp, rotation and drive of the unit. Precise drive control during manoeuvring can be achieved through control hoses located inside the steering tiller.

Power Drive

The power drive system on this unit is powered via the rear of the unit using a steerable tiller. The speed of the drive is adjusted using throttles and an anti-trap switch ensures the operator is kept safe during use. The rear panel features a pressure gauge and an emergency stop button for operators to cut off the unit's power if required.

Rear tiller and control panel

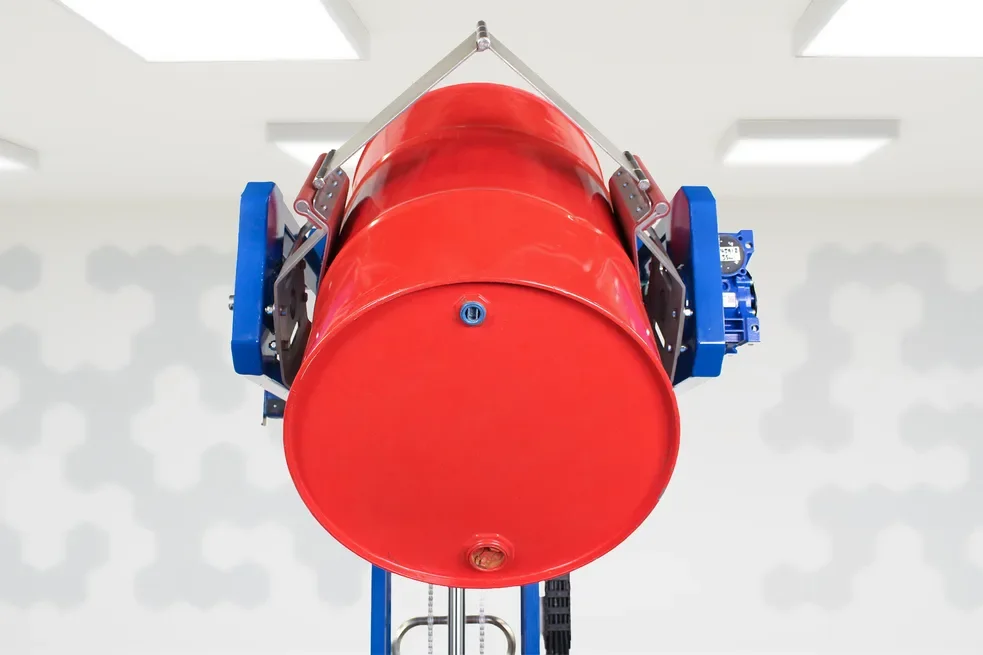

Powered drum clamp and forward rotation

Unlike a banded drum tipping model, this unit has a greater level of powered functionality. Operators wheel the unit towards a drum (located on the floor or the corner of a pallet), clamp the pads around the drum and then lift and tip the contents into a process vessel or secondary container. Powered functions reduce the need for manual interaction with the drum, this is beneficial in saving time and thus improves overall manufacturing cycle times.

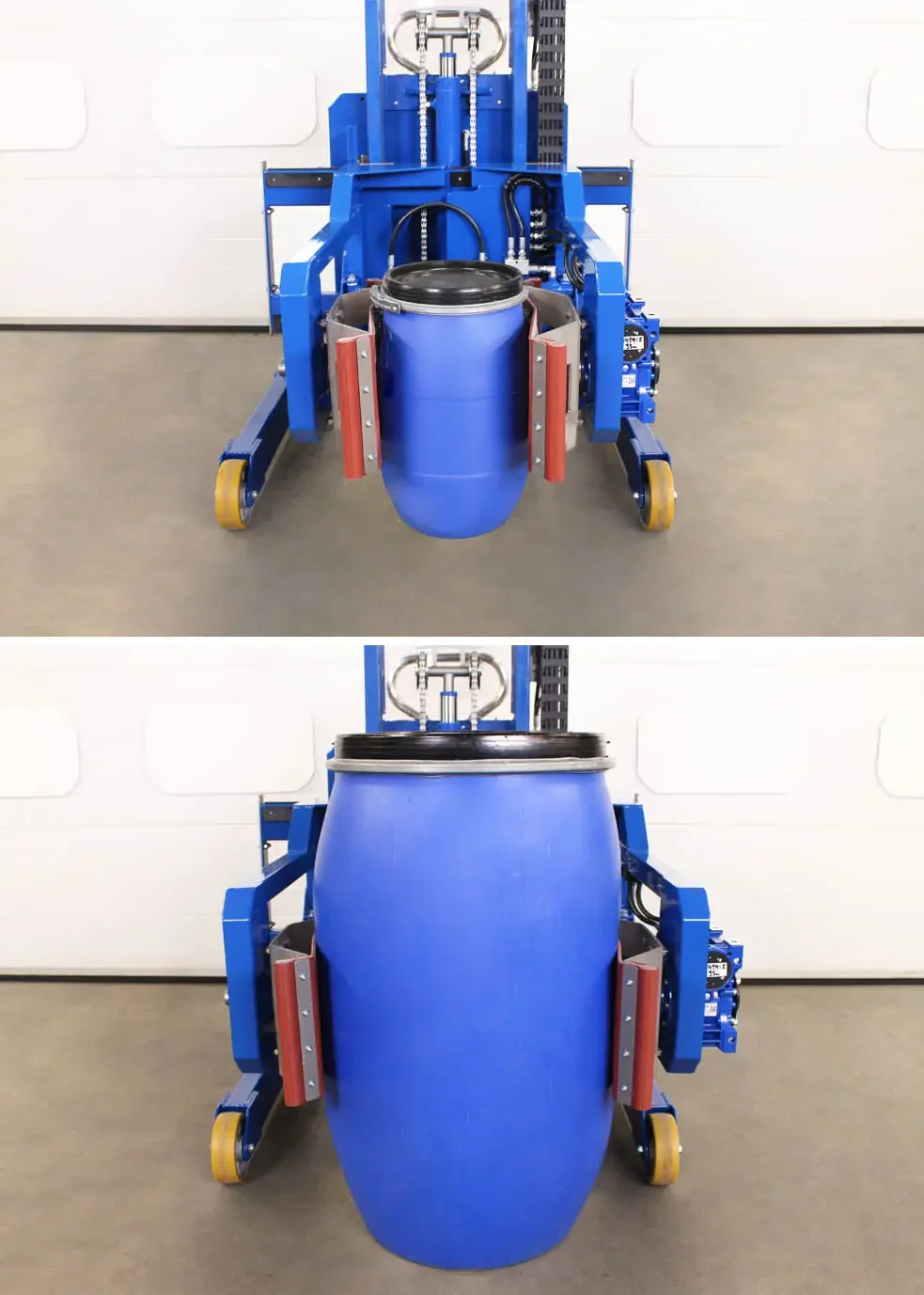

Clamping pad designs

This model can be tailored to suit your process and how you need to handle your drums. Our unique flexible rubber clamping pads are designed to be used with a variety of drum types and sizes 11”-24” (280mm to 610mm) in diameter. The clamping pads can also be configured to allow 55 gallon (205-liter) drums to be removed from the corner of a pallet if this is a requirement.

ATEX / UKEX-certified for gas and dust zones 1, 2, 21 and 22 (optional)

As experts in the field, we have assisted a variety of manufacturing sectors with their hazardous drum-handling processes. Our power-drive pneumatic-hydraulic drum rotators can be supplied ATEX and UKEX compliant, suitable for use in Zone 1, 2, 21 and 22 environments.

Equipment is designed to ensure electrical continuity and that there is always a path to ground. All of our ATEX / UKEX drum handling equipment are supplied with a Declaration of Conformity which states compliance with the directives and relevant British and ISO Standards.

Designed to be as versatile as possible, this power-clamp model can handle a wide range of drum types and sizes. The clamping pads can be provided for handling drums and barrels with a diameter range of between 11” (280mm) and 24.” (610mm). The system has been designed to handle drums of up to 39.37” (1000mm) in height; this covers the majority of drum types used in the market.

Power clamp drum suitability

Technical Specifications

-

Safe working load (SWL)

771lb. (300kg)

Functions

Powered lift, clamp, rotation and drive

Power details

Two, on-board 142Ah batteries powering an electric-hydraulic pump and electric drive motor, mains 230v, smart battery charger built into control box

Controls

Silicone booted buttons, emergency stop, removable key switch, digital battery condition meter

Lift height

59” (1500mm)

Tipping clearance

59” (1500mm) at 15° tip angle / 55” (1400mm) at 30° tip angle 55 gallon (205 liter drum)

Drum compatibility

Steel and plastic drums, 13-58 gallon (50-220 liter) (incl. MAUSER drums)

Clamping system

Two hydraulic clamping arms grip the outside of the drum, the system uses a constant-tension system to keep drum safe and secure

Rotation via gearbox

Rotation via powered gearbox assembly, fully invert drums to 180° to empty the contents

Construction

Mild steel construction

Metal preparation

Grit blasted mild steel, aqua blasted and vibro-polished stainless steel parts

Surface finish

Primer and polyester powder coated mild steel, stainless steel is smooth and clean

Powder coat color

RAL 5010 (blue)

Guarding

Polycarbonate shatterproof clear guarding

Leg dimensions

Inside straddle width 33.46 (850mm), total outside width 42.51 (1080mm)

Front wheels

Two fixed 6.29” (160mm) wheels, aluminum centered with polyurethane tires and precision bearings

Noise

Less than 76 dBA

Compliance

CE / UKCA

-

Safe working load (SWL)

771lb. (300kg)

Functions

Power lift/lower, power clamp, power rotation, manual push/pull

Controls

Silicone booted control buttons and emergency stop

Lift height

59” (1500mm)

Tipping clearance

57.8” (1470mm) at 15° tip angle / 55” (1400mm) at 30° tip angle 55 gallon (205 liter drum)

Drum compatibility

Steel, plastic and fiberboard drums, 13-55 gallon (50-220 liters) (incl. MAUSER drums) (Note: L-ring plastic drums require a separate INS02 attachment)

Clamping head

Hydraulic constant-tension clamping head with pressure gauge for handling all drum types - ‘hands off’ drum handling solution

Powered Rotation

Rotation via powered gearbox assembly, fully invert drums to 180° to empty the contents

Construction

Mild steel construction with stainless steel clamp pads

Metal preparation

Grit blasted mild steel, aqua blasted and vibro-polished stainless steel parts

Surface finish

Primer and polyester powder coated mild steel, stainless steel is smooth and clean

Powder coat colour

RAL 5010 (blue)

Guarding

Anti-static polycarbonate shatterproof clear guarding

Leg dimensions

Inside straddle width 33.46” (850mm), total outside width 42.51” (1080mm)

Front wheels

Two fixed 6.29” (160mm) wheels, aluminum centered with electrically conductive polyurethane tires and precision bearings

Rear wheels

Two tiller steered 6.29” (160mm) wheels, aluminum centered with electrically conductive polyurethane tires and precision bearings

Noise

Less than 76 dBA

‘Ex’ features

Yes

Compliance

CE / UKCA

ATEX / UKEX (zones 1, 2, 21, 22)

Optional Features

Stainless steel

This model can be supplied in 304-grade stainless steel, suitable for good manufacturing practice (GMP) areas as well as clean rooms.

Telescopic variable lift height

Up to 59” (1500mm) of lift height is provided as standard with this model. A telescopic model can also be supplied for tall-lift applications of up to 106” (2700mm).

Variable leg dimensions

We can offer custom leg configurations to suit a variety of applications and usage requirements.

Load-cell weighing system

With our wireless load-cell system you can weigh drums while you lift and tip them. A wireless handheld display shows the drum weight in real time.