Stainless-Steel Drum Pourer with Powered Clamp

Product Code: STE01 / STP01-RRH01-SS-Ex

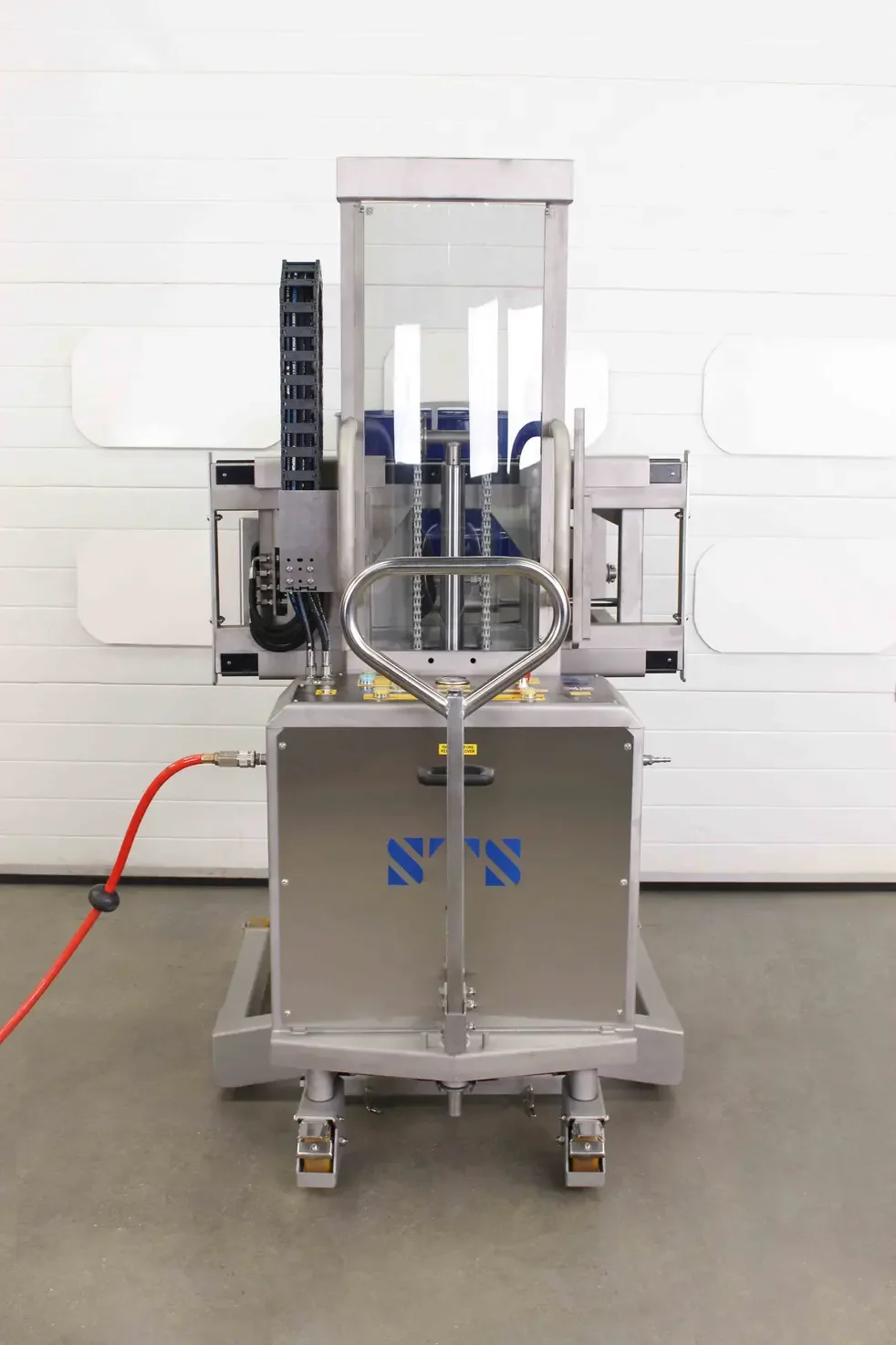

Manufactured in high quality stainless steel this unit is ideally suited to the food or pharmaceutical industries. The ultimate in versatility, our power clamp drum tipper can lift and tip drums and barrels from 50 to 220 litres. This unit can be supplied with electric or pneumatic power sources depending upon your requirements; the pneumatic air powered system (as photographed) requires an airline connection; this version is designed for ATEX and UKEX hazardous areas, zones 1, 2, 21 and 22.

Featuring powered clamp, lift and rotation, this model is a great fit for those companies looking for efficiency gains in departments that handle drums. All our units are installed with fully-compliant lift circuits; STS qualified engineers install all our units with the mandatory safety features and emergency stops to keep operators safe during use.

This stainless steel power-clamp drum tipper also features a clamp pressure gauge to allow operators to monitor the clamp pressure during use. Additionally, the hydraulic rams are protected by burst valves should a hose or fitting be damaged during use.

Fully compliant circuits

Powered drum clamp and forward rotation

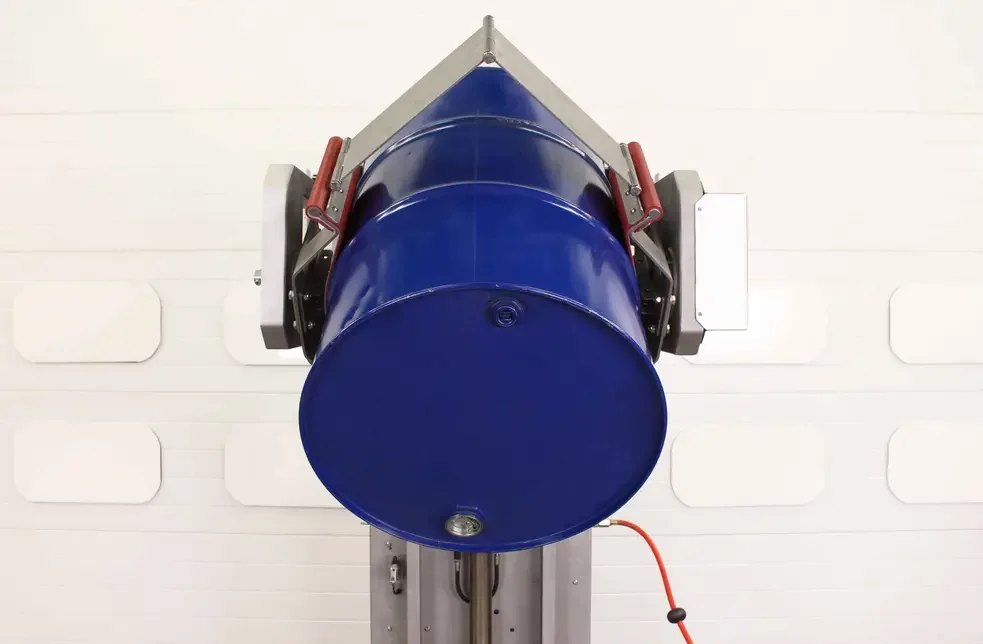

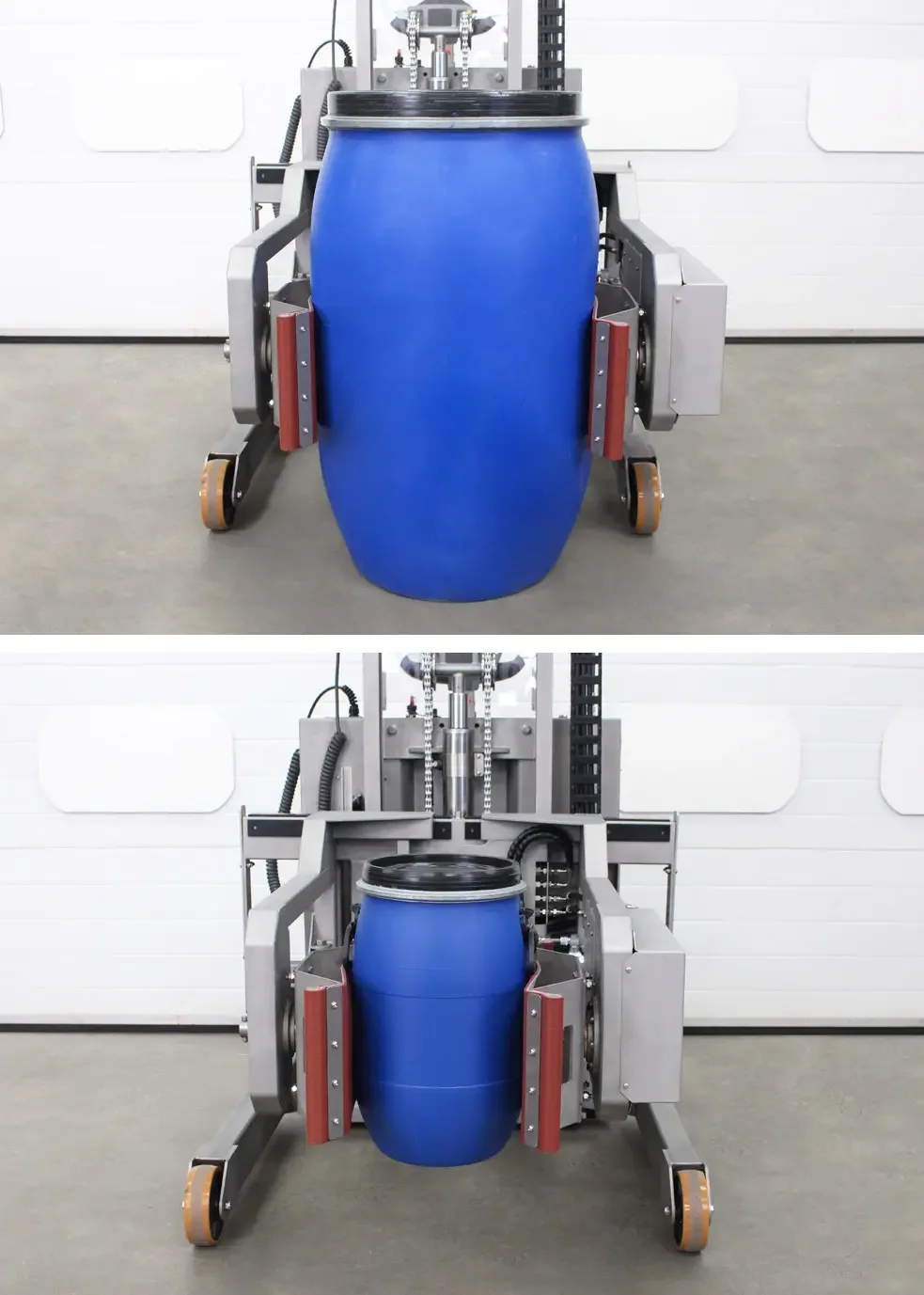

This unit has a hydraulic-powered clamping head with powered drum rotation. These powered features save time for operators and allow the unit to be fully operated from the rear panel. Operators simply approach a drum, clamp the arms around it by pressing the 'clamp' button, press 'lift', and then press 'rotate' to empty it. The machine provides ample reach when tipping into large vessels or machines. We can modify the tipping clearances to suit your exact requirements.

The flexible pads adapt to the contours of the drums and are able to accommodate a wide range of drum diameters from 11”-24” (280mm-610mm). The power-clamp pads are configured to allow drums to be removed from the corner of a pallet if needed. When lifting drums on and off pallets we can also offer a dedicated drum lifter from our range.

Each gripping head can be adapted to suit your specific lifting application. If you have custom-made drums or unique drums we can provide tailor-made gripping pads to ensure these containers can be clamped, lifted, and tipped safely and easily.

Clamping pad designs

Our power-clamp unit is universal by design and is suitable for handling a wide range of drum types and sizes. The versatile clamping pads are suitable for handling drums with a diameter range of between 11” (280mm) and 24” (610mm) and of up to 39.37” (1000mm) in height.

The clamping arrangement can accommodate steel, plastic, and fiberboard drums. Very soft or flexible drums will need to be handled with care as the hydraulic clamping force can distort these. L-ring plastic drums will require a separate INS02 attachment due to their unique properties. Please get in touch with information on your drum types and sizes to check compatibility.

Power clamp drum suitability

We construct these machines from 304-grade stainless steel and treat the surface to ensure they have a smooth clean finish - operators can easily clean and disinfect the unit between uses if needed.

The unit is fitted with Ackermann-style rear-wheel steering giving maximum control when tipping drums into your process; the wheels are 6.29” (160mm) in diameter and contain two precision bearings. We fit rear operator-controlled park brakes on all drum tipper models to ensure the unit remains stationary when it is left unattended. STS can help with custom leg configurations if this is a requirement for example when interfacing with a wide vessel or narrow machine.

Controllable rear-wheel steering

ATEX and UKEX-certified for gas and dust zones 1,2, 21 and 22 (optional)

When explosive or potentially explosive atmospheres exist, we are able to supply ATEX and UKEX compliant drum tipping equipment. Our pneumatic-hydraulic model can be certified for use in Zone 1, 2, 21 and 22 environments. Unfortunately, we are not currently able to offer an electric ATEX or UKEX drum tipper as part of our range; it is possible to get an electric model converted by a 3rd party if required.

Each of our 'Ex' rated drum handlers is designed to ensure electrical continuity, a path to ground is always present. We supply a manufacturer’s Declaration of Conformity which states compliance with the directives and relevant British and ISO Standards.

Technical Specifications

-

Safe working load (SWL)

661lb. (300kg)

Functions

Powered lift/lower, powered clamp, powered rotation, manual push/pull

Power details

Two onboard 80Ah batteries power an electric-hydraulic pump. Mains 230v smart battery charger built into the control box

Controls

Silicone booted buttons, emergency stop, removable key switch, digital battery condition meter, clamp pressure meter

Lift stroke

59.6” (1515mm)

Tipping clearance

55.7” (1415mm) at 15° tip angle / 52.6” (1338mm) at 30° tip angle 55 gallon (205 liter drum)

Drum compatibility

Steel and plastic drums, 13-58 gallon (50-220 liter) (incl. MAUSER drums)

(Note: L-ring plastic drums require a separate INS02 attachment)

Clamping head

Hydraulic constant-tension clamping head with pressure gauge for handling a wide range of drum types - ‘hands off’ drum handling solution

Powered rotation

Rotation via powered gearbox assembly, fully invert drums 180° to empty the contents

Construction

Stainless steel 304-grade construction

Metal preparation

Aqua blasted and vibro-polished stainless steel parts, smooth clean finish

Guarding

Polycarbonate shatterproof clear guarding

Leg dimensions

Inside straddle width 33.46” (850mm), total outside width 42.5” (1080mm)

Front wheels

Two fixed 6.29” (160mm) wheels, plastic centered with polyurethane tires and precision bearings

Rear wheels

Two tiller steered 6.29” (160mm) wheels, plastic centered with polyurethane tires and precision bearings

Noise

Less than 76 dBA

ATEX features

No

Compliance

CE / UKCA

-

Safe working load (SWL)

661lb. (300kg)

Functions

Powered lift/lower, manual rotation, manual push/pull

Power details

Air powered - requires min: 106gallon/min (400L/min), optimum: 200 gallon/min (760L/min) at 6 bar with 1/2” (13mm) flexible air hose

Controls

Silicon booted buttons, emergency stop, removable key switch, digital battery condition meter

Lift stroke

59.6” (1515mm)

Tipping clearance

55.7” (1415mm) at 15° tip angle / 52.6” (1338mm) at 30° tip angle 55 gallon (205 liter drum)

Drum compatibility

Steel and plastic drums, 13-55 gallon (50-220 liter) (incl. MAUSER drums)

Clamping head

Hydraulic constant-tension clamping head with pressure gauge for handling all drum types - ‘hands off’ drum handling solution

Powered Rotation

Rotation via powered gearbox assembly, fully invert drums 180° to empty the contents

Construction

Stainless steel 304-grade chassis, steel zinc/nickel-coated hydraulic lift ram, aluminum hand pump assembly in stainless steel shroud

Metal treatment

Vibro-polished stainless steel parts, smooth clean finish

Guarding

Polycarbonate shatterproof clear guarding

Leg dimensions

Inside straddle width 33.46” (850mm), total outside width 42.5” (1080mm)

Front wheels

Two fixed 6.29” (160mm) wheels, plastic centered with polyurethane tires and precision bearings

Rear wheels

Two tiller steered 6.29” (160mm) wheels, plastic centered with polyurethane tires and precision bearings

Noise

Less than 76 dBA

Compliance

CE / UKCA / ATEX / UKEX (zones 1, 2, 21, 22)

Optional Features

EX - ATEX Option

We can offer an ATEX / UKEX version of this drum rotator model, suitable for use in zone 1, 2, 21 and 22 environments.

Powered drive system

When moving drums over long distances you may need power drive. Our electric power-drive tiller steering offers effortless control.

Variable leg dimensions

We can offer custom leg configurations to suit a variety of applications and usage requirements.

Load-cell weighing system

With our wireless load-cell system you can weigh drums while you lift and tip them. A wireless handheld display shows the drum weight in real time.

Telescopic/variable lift height

Single and dual-mast models are available, depending on the lift height required. Single masts offer around 59”(1500mm) lift whereas telescopic masts offer 106.29: (2700mm).