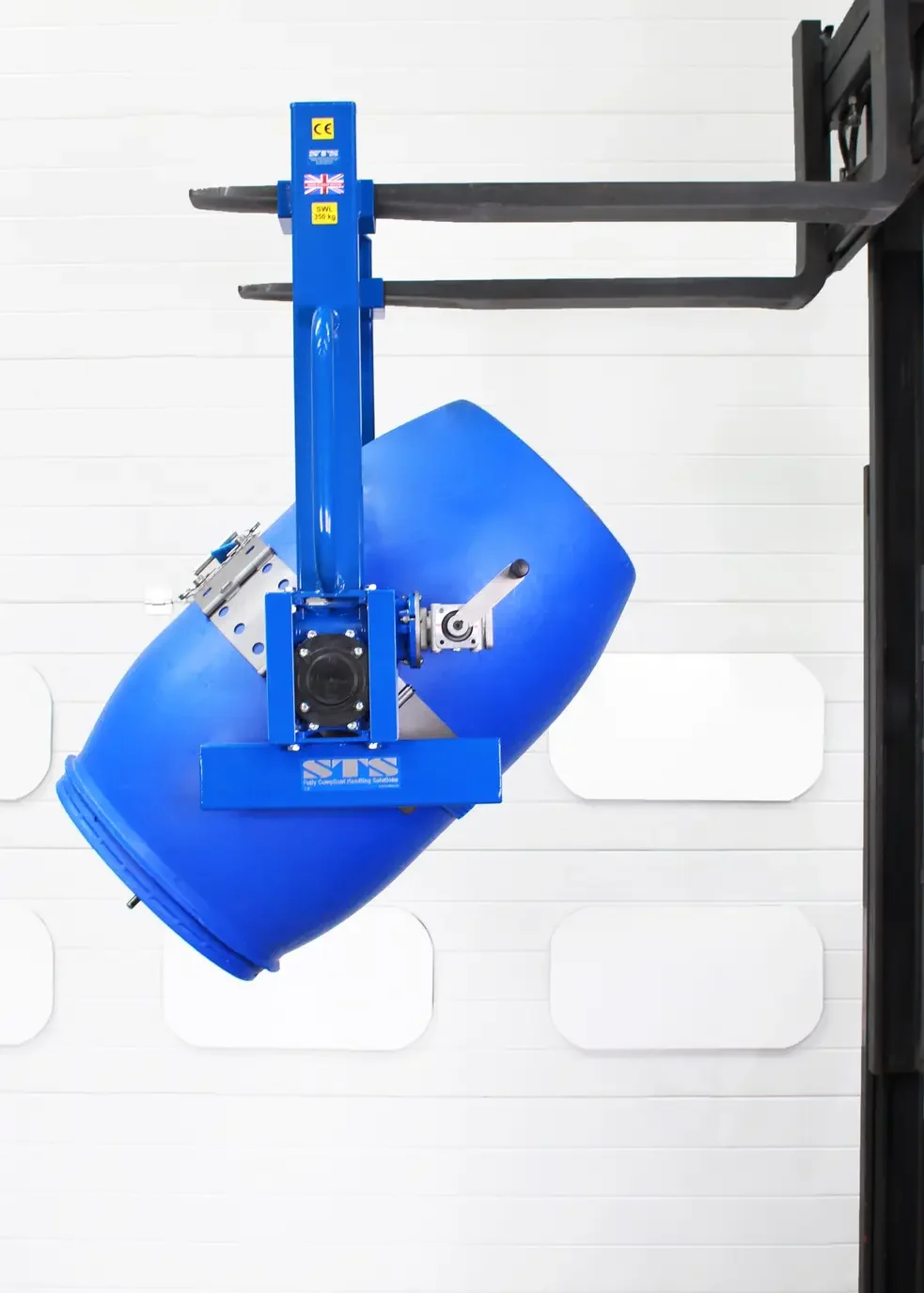

Overhead Drum Rotator (Fixed Band)

Product Code: DRU02-FB

Dual purpose, this unique drum handler can be used below hook with your hoist or crane and as a forklift attachment. This model uses a stainless steel over-center clamping band. Accommodates drums from as small as 13 gallons (50 liters) up to 55 gallons (220 liters), whether steel, plastic or fiber. The rim-locking device provides a second securing method, eliminating any risk of the drum slipping while being poured or decanted.

Large lifting pin and fork pockets

With two distinct pick-up points, the Overhead Drum Rotator (Fixed Band) is a great choice if you need a versatile drum handler for pouring and decanting. The large central lifting pin has been designed for use with an overhead crane, derrick or hoist. Fork pockets are installed beneath the top beam to allow mounting onto a stacker or forklift truck.

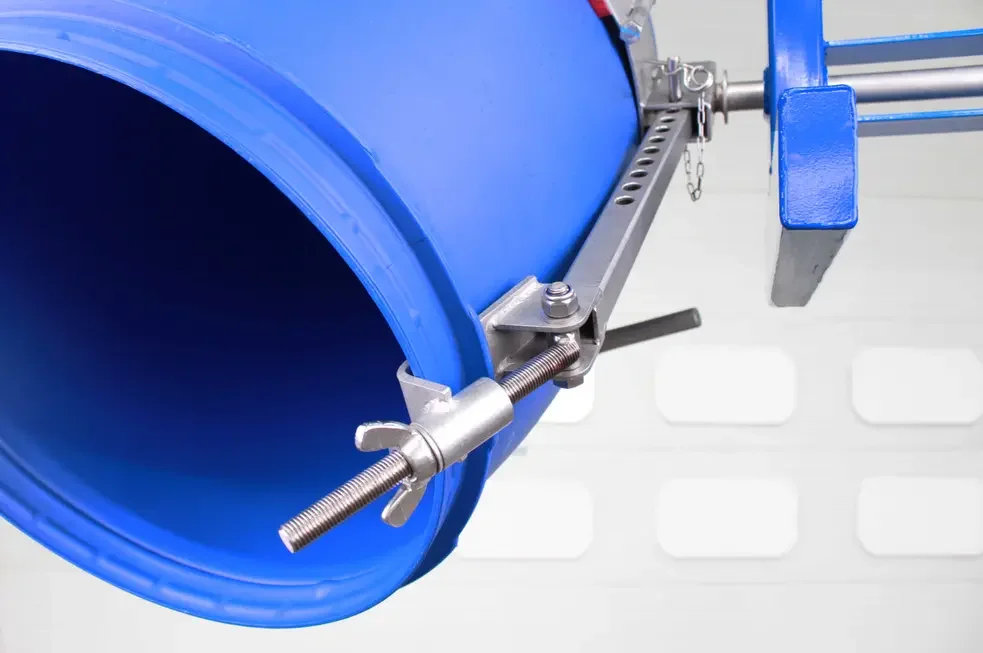

Sliding pivot

The fast-acting over-center clamp is adjustable to allow drums from 22.8”-23.6” (580mm-600mm) in diameter to be clamped 52-58 gallon (200 to 220-liter drums). Made out of stainless steel and manufactured in the UK, the securing system is extremely durable and robust. If you handle drums of varying sizes, we also supply an Overhead Drum Rotator, which is designed with a universal band, accommodating drums from 13-58 gallons (50 liters to 220 liters).

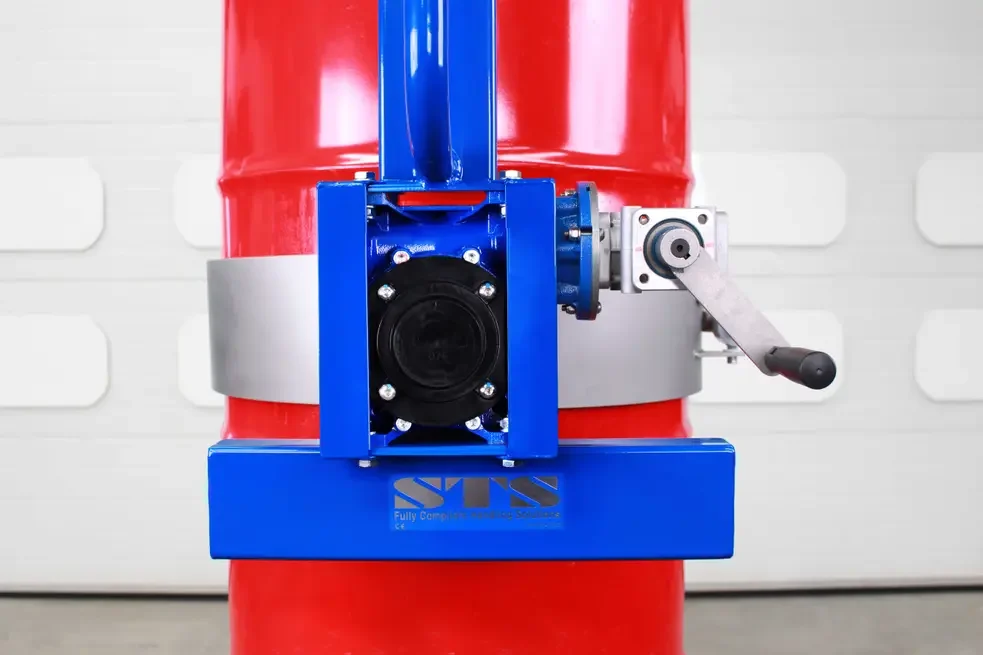

Self-locking gearbox

A high-quality self-locking rotational gearbox ensures drums never self-rotate. Operators rotate drums by hand by turning the gearbox input handle. With an ergonomic gearbox ratio of 120:1, it is easy for any operator to decant drums in the workplace.

Rim-clamp securing system

The drum rotator comes with a rim-locking device, which attaches to the lip of the drum to add a second level of security. This allows you to safely handle a vast range of drums, some of which cannot be handled by other equipment on the market.

Drum Suitability

Our Overhead Drum Rotator is suitable for a wide range of drum types, sizes and materials. For a detailed list of compatible drum types, see the drum suitability document below.

Optional Features

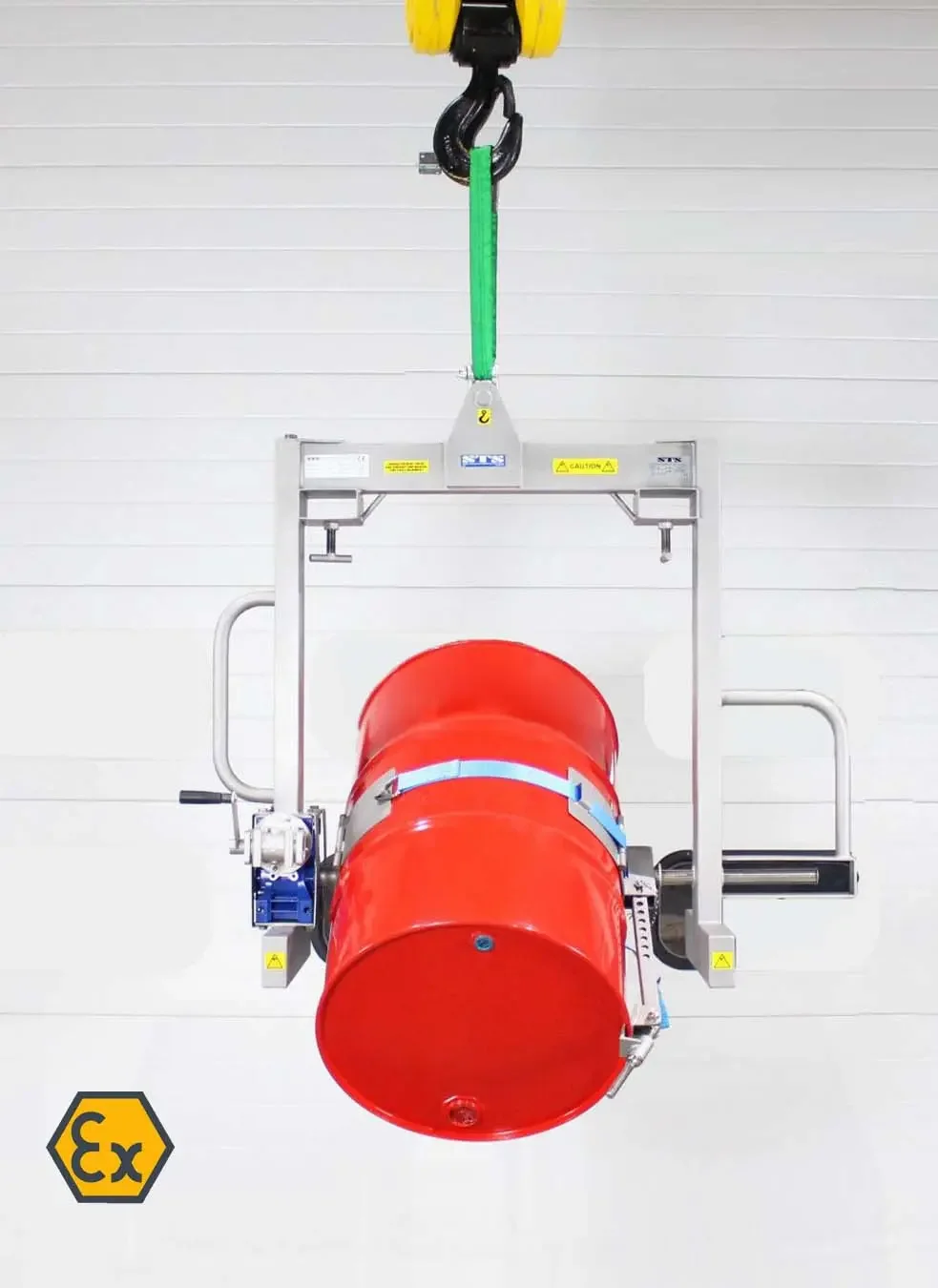

Stainless steel

This model can be supplied in 304-grade stainless steel, suitable for good manufacturing practice (GMP) areas as well as clean rooms.

EX / ATEX

Suitable for use in hazardous zoned areas. The DRU02-SS-EX is constructed from 304 grade stainless steel. Eliminates any thermic-strike risk. Suitable for gas and dust areas.

Load cell weighing system

We are able to offer an Overhead Drum Rotator with an integrated load-cell. Weigh drums at the same time as you decant from them using the unique system.

-

Safe working load (SWL)

771 lb. (350kg)

Drum compatibility

Steel and plastic drums, 52-58 gallon (200-220 liters)

Band assembly

Fixed rotator band with fast-acting over-center clamp

Additional drum securing

Rim clamp included which grips the top edge of the drum preventing slippage

Rotation gearbox

Worm-wheel, self-locking with 120:1 ratio and manual handle

Construction

Mild steel chassis, stainless steel rotator band assembly

Metal preparation

Grit blasted mild steel, aqua blasted and vibro-polished stainless steel parts

Surface finish

Primer and polyester powder coated mild steel, stainless steel is smooth and clean

Powder coat color

RAL 5010 (blue)

Compatible with overhead crane

Yes, large lifting pin

Compatible with forklift truck

Yes, fork pockets included

Compliance

CE / UKCA

-

Safe working load (SWL)

771 lb. (350kg)

Drum compatibility

Steel and plastic drums, 52-58 gallon (200-220 liters) (incl. MAUSER drums)

Band assembly

Segmented adjustable/universal band with 1.96” (50mm) stainless steel ratchet and polyester strap

Additional drum securing

Rim clamp included which grips the top edge of the drum preventing slippage

Rotation gearbox

Worm-wheel, self-locking with 120:1 ratio and manual handle

Construction

Stainless steel chassis and rotator band assembly

Metal preparation

Aqua blasted and vibro-polished stainless steel parts

Surface finish

Smooth clean stainless steel finish

Compatible with forklift truck

Yes, fork pockets included

Compatible with overhead crane

Yes, large lifting pin

Compliance

CE / UKCA

ATEX / UKEX (zones 1, 2, 21, 22)